CCTV Report: Biodegradable Plastics Will Be Fully Promoted by the End of This Year!

CCTV news: In recent years, the whole country has introduced regulations and measures related to "plastic ban" one after another. It is urgent to control "white pollution" and protect the environment, and the biodegradable materials industry has been on the fast track of rapid development.

According to the Opinions on Further Strengthening Plastic Pollution Control issued by National Development and Reform Commission and Ministry of Ecology and Environment in 2020, by the end of this year, non-biodegradable plastic products will be banned from being used in stores, pharmacies, restaurants, express delivery and other places in the built-up areas of cities above prefecture level and counties in coastal areas, which means that biodegradable plastic will be promoted in all prefecture level cities in China by the end of this year.

On June 1 this year, the two recommended national standards of Biodegradable Plastics and Products Degradation Performance and Marking Requirements and Biodegradable Drinking Straws were officially implemented, which means that the promotion and application of biodegradable material products has been speeded up significantly.

Yesterday (19th), the demonstration project of 50,000 tons per year of polyglycolic acid biodegradable material of National Energy Group Yulin Chemical Company was put into production after passing all the production processes.

The biodegradable materials produced by the project can replace a large number of disposable plastic products and can be completely and harmlessly degraded in the natural environment such as soil and seawater in only six months to one year.

Yan Guochun, head of polyethanolic acid degradable material project of National Energy Group: Through years of innovation and practice, we can produce not only traditional plastics with coal, but also degradable plastics like polyethanolic acid. Compared with the production of traditional plastics, the coal consumption per ton of polyethanolic acid can be reduced by 1/2, and the CO2 emission during the production process is reduced by 2/3. With the technological progress and scale up, the cost can be close to the production cost of traditional plastics.

The products of this project can not only be made into disposable tableware, plastic bags and other daily necessities, but also have very wide application space in high-end fields such as medical surgical sutures, agricultural mulch and underground unconventional oil and gas extraction. It will promote the comprehensive utilization of coal chemical industry in China, and develop in the direction of "high-end, diversification and low carbonization".

Liu Zhongmin, member of Chinese Academy of Engineering, Director of Dalian Institute of Chemical Physics, Chinese Academy of Sciences: Biodegradable plastic is a new direction, from the perspective of the world, the output is less than 1%, its replacement space is also tens of millions of tons, which means that the market space is also huge. Together with the effect of emission reduction, carbon reduction and cost reduction, it can be expected that coal chemical industry will be a new direction of rapid development for degradable plastics.

Biodegradable materials change people's lives

What will biodegradable materials bring to our lives and what difference does it make to use them? In order to understand the application of biodegradable materials in real life, researchers have conducted demonstration and promotion in some communities in advance, and go together to see how the residents use it.

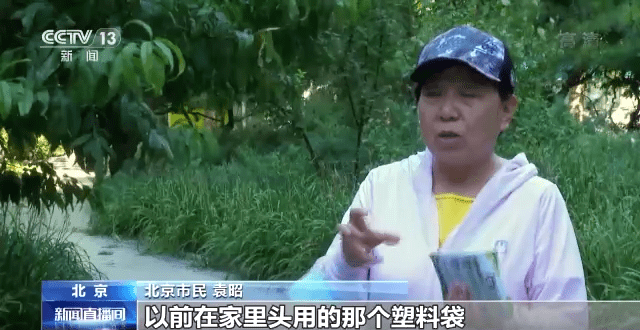

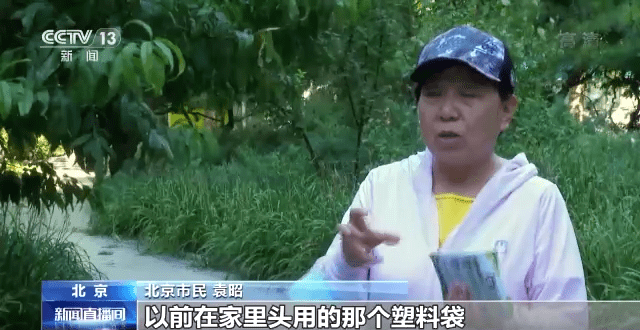

The most widely used biodegradable materials are the garbage bags that every household can't live without. According to the regulations of Beijing's garbage classification, food waste needs to be unpacked and put into the garbage bin, that is, the garbage is directly dumped into the food waste bin, and the plastic garbage bags are separately thrown into other garbage bins. But the actual operation is both troublesome and unhygienic. This has also become one of the biggest pain points and difficulties in waste separation. In response to this situation, starting from April this year, researchers have been carrying out pilot work of biodegradable garbage bags in several communities in Beijing. Up to now, nearly 1.2 million garbage bags have been distributed. Ms. Yuan, who originally worked as a garbage sorting supervisor in the community, has deep feelings about the changes before and after using biodegradable garbage bags.

Yuan Zhao, Beijing citizen: The plastic bags used at home before, as well as this soup and water food waste will certainly cause this kind of special dirty to the overall environment, and also especially smelly in the summer time. Now with this biodegradable garbage bags, directly thrown in the garbage can. The whole outside garbage can is really a lot cleaner.

At the biodegradable demonstration integrated waste treatment plant on the outskirts of Shunyi, Beijing, there are about 5 tons of food waste shipped from the pilot community every day. It can be seen that a large number of biodegradable garbage bags are mixed directly in the garbage and can be completely degraded in only 27 days under a specific aerobic composting environment. Biodegradable materials are not only used in garbage bags, but also can be widely used in disposable tableware, agricultural land film, and even medical, clothing and other areas closely related to our lives.

Weng Yunxuan, Secretary General of China Plastics Processing Industry Association Degradable Plastics Professional Committee: You can see that I am wearing PLA degradable material clothes. There are many people ask: will these biodegradable material clothes disappear while wearing? It does not, because biodegradation requires certain conditions, it has to be in the soil, it has to have moisture, it has to have temperature, it has to have microorganisms. When we usually wear it on our body, there is no degradation conditions, it will not degrade. The quality is still very good, you can see that I have washed this clothes on a dozen times and it is fine.

Yan Guochun, head of NEC's polyglycolic acid degradable material project: At present, polyglycolic acid is mainly used as a biomedical material with excellent biodegradable properties, good mechanical properties and biocompatibility, which can be used for bone and nerve tissue engineering to guide bone and nerve regeneration and gradually degrade during the process of tissue repair to avoid secondary surgical damage. The cost of polyglycolic acid we produce from coal is significantly reduced, which can make this high-end material replace disposable plastic products and play an important role in combating white pollution.

Source: CCTV

(Disclaimer: This article is reproduced for the purpose of conveying more information. If there are sources marked wrong or violate your legitimate rights and interests, please contact us with proof of ownership, we will correct and delete in time, thank you. (E-mail: contact@xcgs.com)

18915559236

18915559236 xcbxa@xcgs.com

xcbxa@xcgs.com