The annual Double Eleven shopping carnival is finally over. After experiencing the joy and passion of unpacking the express delivery, have you ever cared about the packaging bags that were left aside? Bubble bags are the most common and common express packaging bags. A simple bubble bag weighs only a few tens of grams, but it can keep the goods inside safely deliver the package to your hands. How does it do it?

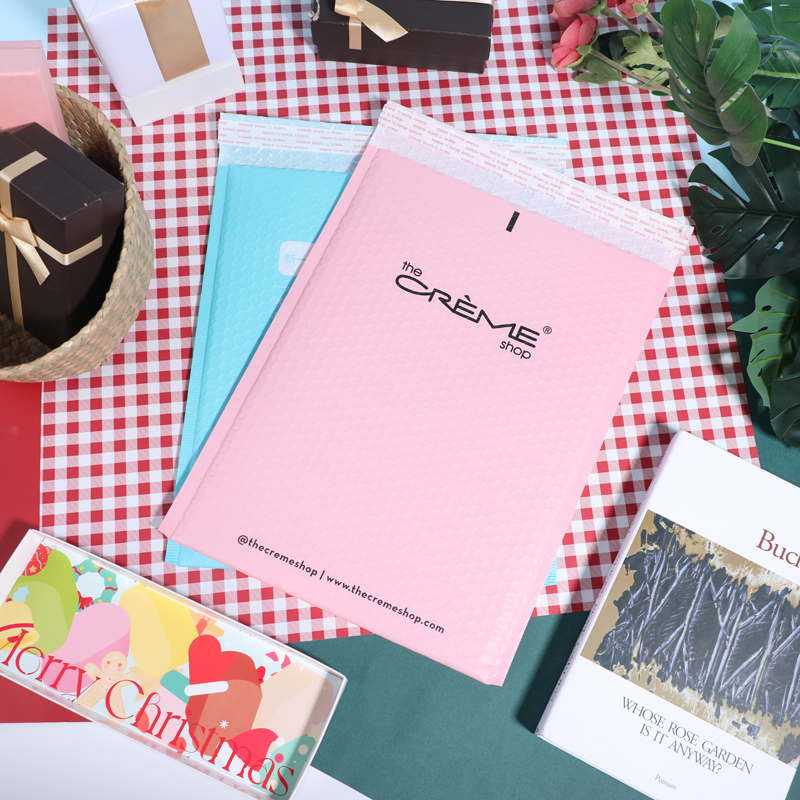

Bubble bag, as the name suggests, is a bag made of one or more layers of bubble film. It is light and elastic, and can play a role of cushioning and protection when the package is under heavy pressure or puncture. Common bubble bags on the market are attached with a layer of surface film, which can be printed with colors and patterns, making the original ordinary bubble bags colorful and diverse, while also being moisture-proof, waterproof and light-blocking function.

According to the different films on the surface, bubble bags can be basically divided into the following categories:

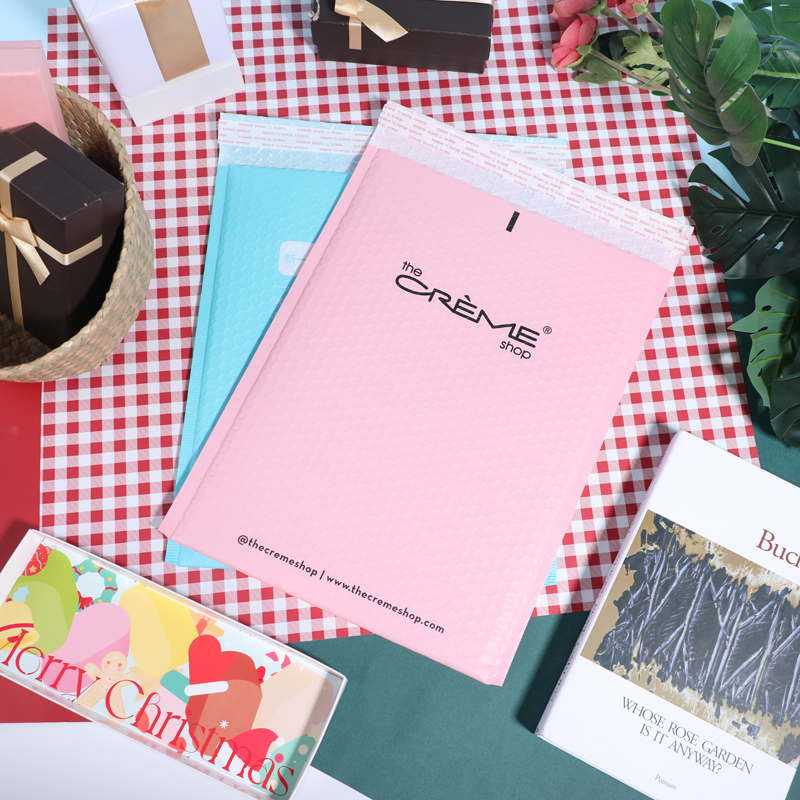

★1. Poly Bubble Bag

Co-extruded film is a kind of film in which various plastic materials are extruded and formed simultaneously through a co-extrusion die. It has the advantages of good stretchability and good surface color.

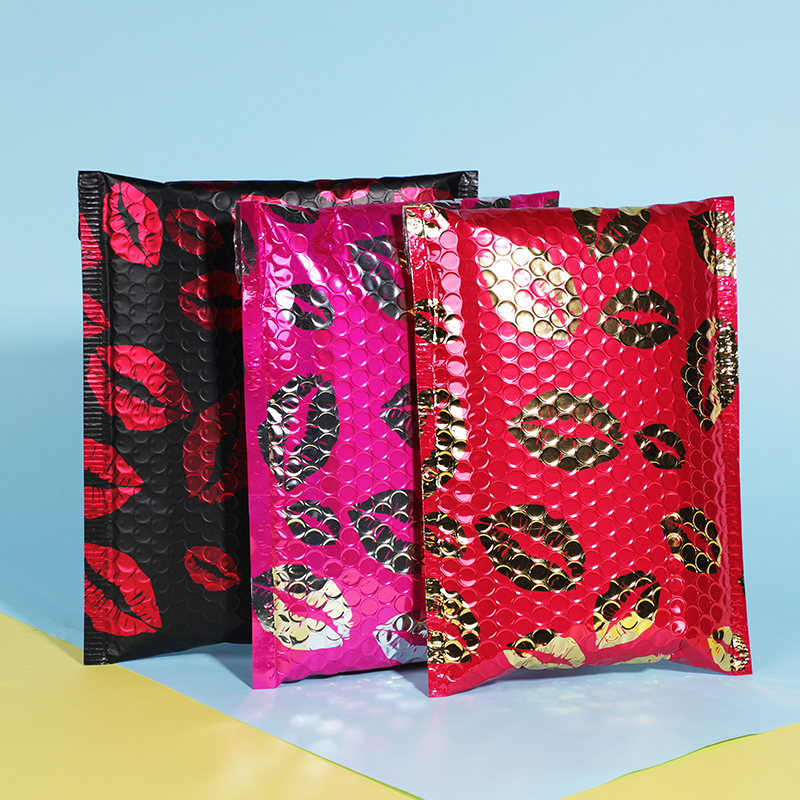

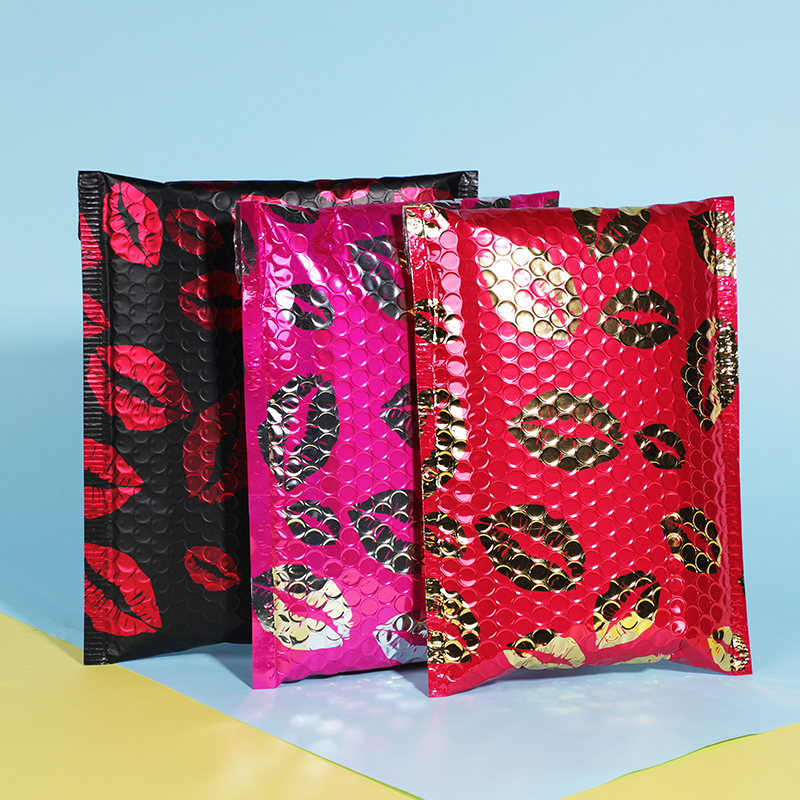

★2. Metallic Bubble Bag

Aluminum-coated film is to evaporate high-purity aluminum into a gaseous state at high temperature (1100~1200°C), and then deposit aluminum vapor on the surface of the plastic film to form a film with metallic luster, which has excellent gas barrier properties and barrier properties. Humidity, light-shielding and fragrance retention.

★3. Pearl Film Bubble Bag

Pearlescent film is a film made of polypropylene resin, adding calcium carbonate and pearlescent pigments, etc., and biaxially stretched after mixing. The surface has the same color as pearls. It has strong decorative properties and good barrier properties.

★4. Milk White Film Bubble Bag

The milky white film is made of special polyethylene material film as the base material, and then processed with several special additives. It is soft in texture, has the characteristics of wear resistance, scratch resistance, and good tear resistance.

★5. Kraft Paper Bubble Bag

Kraft paper is a tough packaging paper. It is made of wood fiber and has a brownish yellow color. It can also be made into white and other colors. It is 100% recyclable and degradable, and is environmentally friendly.

After understanding the classification of bubble bags, let's take a look at how to quickly and easily distinguish the advantages and disadvantages of bubble bags?

▲1. Check the appearance:

Bubble bags are generally made of high-quality PE material, with clear and transparent color and smooth surface. If there is yellowing or dull color, such bags are likely to be mixed with recycled old materials.

▲2. Check the hand feeling:

the high-quality air bubble bag is smooth and fine, without graininess; while the garbage film is unevenly melted due to impure ingredients, and you will feel fine graininess when you touch it.

▲3. Check the workmanship:

High-quality cushioning bubble bags are often atmospheric and beautiful, and the workmanship is meticulous. On the contrary, if it is a poor-quality bag, the workmanship is often poor, and there are usually problems such as poor sealing adhesiveness, rough lines, and even serious problems such as air leakage.

Through the above introduction, do you think that the humble bubble express bag has so many ways! The bubble bag is the protection tool of the product and the messenger of the brand. The high-quality and beautiful bubble bag can make the product reach the user intact and leave a good impression on the customer at first sight.

18915559236

18915559236 xcbxa@xcgs.com

xcbxa@xcgs.com